Larssen Sheet Piles

What are Larssen Sheet Piles?

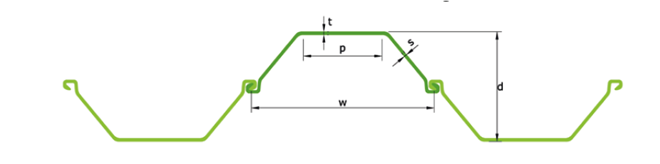

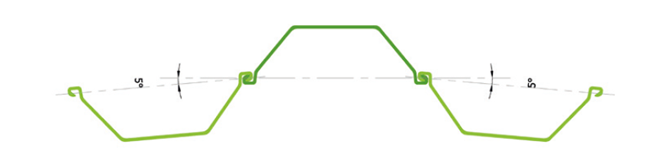

Larssen Piles are a type of sheet piling that has an interlocking section which forms a sheet piling retaining wall. Each sheet pile section is connected at 180 degrees from the previous one to form a uniform wall with alternating troughs and peaks.

What Can Larssen Sheet Piles be used for?

Larssen Sheet Piles are typically used in temporary or permanent cofferdams, retaining walls and foundation construction. Available in a range of sheet pile size, Larssen piles are also commonly used for marine projects due to the watertight quality of the interlocking section. Depending on ground conditions, consideration must be given to the length of the pile to be driven, depth of penetration and ground loadings.

What are the benefits of Larssen Sheet Piles?

The sheet pile sections are designed to be as light as possible without compromising strength and durability and have a high strength to weight ratio. With lengths up to 18 metres, Larssen Piles combine reduced deflections with good driving properties and durability. Piletec offer a comprehensive range of heavy Larssen sheet pile section profiles and lengths.

How to Hire Larssen Sheet Piles from Piletec?

For more information on hiring Larssen Sheet Piles, or for advice on what type of sheet piling would suit your project, simply follow our Contact Us link or ‘Add to Enquiry Basket’ to find out what’s on offer, or send for a product brochure.

Key Specifications of Larssen Sheet Piles

The table below gives detailed specifications for each sheet pile profile to assist designers in specifying the most appropriate sheet type for any given temporary works application.

| Sheet Type |

'w' Width (m) |

't' pan thickness (mm) |

's' web thickness (mm) |

'd' pan depth (mm) |

'p' pan width (mm) |

Cross section area (cm2/m) |

Weight (single pile) |

Weight (kg/m2) |

Permissable working stress (N/mm2) |

Section Modulus (cm3/m) |

Moment of Inertia (cm4/m) |

Maximum bending moment (kNm/m) |

| PU12 |

0.6 |

9.8 |

9.0 |

360 |

258 |

140 |

66.1 |

110.1 |

200 |

1200 |

21600 |

240 |

| PU18-1 |

0.6 |

10.2 |

8.4 |

430 |

269 |

154 |

72.6 |

121.0 |

200 |

1670 |

35950 |

334 |

| PU22-1 |

0.6 |

11.1 |

9.0 |

450 |

297 |

174 |

81.9 |

136.5 |

200 |

2060 |

46380 |

371 |

| PU22+1 |

0.6 |

13.1 |

10 |

450 |

297 |

192 |

90.4 |

150.7 |

200 |

2335 |

52510 |

467 |

| PU28-1 |

0.6 |

14.2 |

9.7 |

452 |

339 |

207 |

97.4 |

162.3 |

200 |

2680 |

60580 |

536 |

Note: All hire piles are classed as steel grade S270. All grades available for sale.

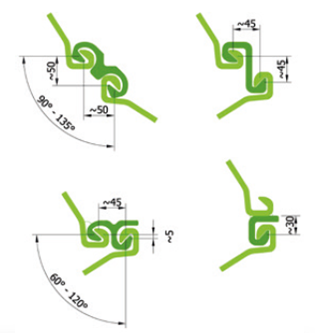

Corner sections

Various corner sections are available for applications where fully closed cofferdams are required (high water table, poor

ground conditions etc.). This will offer the advantage of greater water/fine material retention. The use of corner sections

will result in specific excavation dimensions depending on the combination of piles/corner sections used.

| Corner Pile |

Weight (kg/m) |

't' thickness (mm) |

Steel Grade |

Permissible working stress (N/mm2) |

| Omega 18 |

18.0 |

8 |

S270 |

200 |

| C14 |

14.4 |

10 |

S270 |

200 |

| Delta 13 |

13.1 |

8 |

S270 |

200 |

| C9 |

9.3 |

10 |

S270 |

200 |

Note: Piletec are able to advise customers of exact cofferdam dimensions by the use of their Sheet to Sheet pile

configuration software as a means of calculating cofferdam size for a combination of pile/corner/junction combinations.

Please contact Piletec Technical Services for further advice.